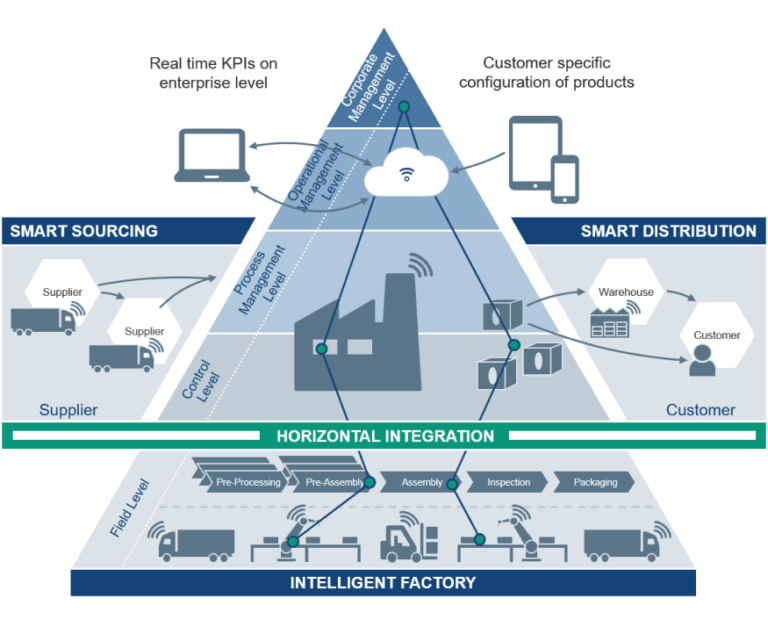

Manufacturing Intelligence (IIoT) is used to collect manufacturing-related corporate data from many sources for reports, analysis, visual summaries and data transfer between the business level and plant-floor frameworks. It helps in:

- Accumulation: Create accessibility of information from many sources, mostly databases

- Contextualization: Provide a construction, or model, for the information that helps clients discover what they need.

- Analytics: Allows users to analyze data from all sources, especially at production sites. This often includes the ability to generate real ad hoc reports.

- Visualization: Provide tools to create visual summaries of data to alert decision makers and make them aware of the most important timely information vice versa

- Proliferation: Automate the exchange of information from the plant floor up to big business level frameworks or the other way around

How do we do this?

- Connecting manufacturing plants around the world

- We have developed a system that records numerous data points per minute around the clock

- With a data lake we process more than 4 million new manufacturing data points per day

- Applying Almost real-time business Rules using a configurable rules engine

- Detection of cycle time, downtime, changes and performance conditions

Envisioning plant information on central dashboards - Carrying manufacturing information in your pocket, on your mobile phone

Main advantages of using IIoT

- Proactive vs. reactive

- Use Big Data to Make Strategic Decisions

- Monitor Your Manufacturing Process from A to Z

- Generate Real-Time Anomaly Alerts

- Unified View

- Quality Monitor

- Track Your Parts

- Management Dashboards

- People User Onalization

- Analysis platform Integration

Short-term (3-12 months)

- Increase in efficiency

- Lower costs

- Improve quality

Medium-term (12-36 months)

- Process improvements

- Reduced cycles / workflows

- Decreased stock convey costs

Long-term ( over 3 years)

- Accelerated new product introduction

- Reduced indirect labor costs

- Better decision support for management

- Increased organizational agility

- Better asset utilization

IIoT solution are User Personalized

- Workforce in all levels gets “exactly” what they need

- Problem notifications, “Urgency” level

- Notify the right people in the correct order if the problem worsens & not resolved within defined parameters

- Notification for resolution to the management on the solution / conclusion assessing the problem, the time required, informing those responsible, etc.

- Real-time escalation of problems to regional or global technical experts